3D printing is making significant strides in the field of healthcare. This revolutionary technology has already demonstrated its potential to improve surgical techniques, create organ models, develop bone and joint implants, and produce precision instruments. Moreover, researchers are exploring the possibility of manufacturing medications, skin tissue, and even organs using 3D printing.

The adoption of 3D printing in healthcare is on the rise. In 2019, there were 113 hospitals equipped with in-house 3D printing facilities, compared to just three in 2010. The FDA has approved numerous medical products made with 3D technology, and during the COVID-19 pandemic, hospitals relied on 3D printing to rapidly produce personal protective equipment and medical devices.

As medical device manufacturers increasingly utilize 3D printing to reduce costs and meet supply demands, healthcare providers are taking a closer look at this technology. While unanswered questions remain about the future prevalence of 3D printing in healthcare and the reimbursement policies surrounding it, let’s explore some of the current ways hospitals and health systems are benefiting from 3D printing and how it may transform clinical care in the future.

How 3D Printing Is Impacting Clinical Care

3D printing involves creating a three-dimensional solid object from a digital model. The printer reproduces the object layer by layer with filament and ultraviolet light, eliminating the need for expensive and bulky traditional manufacturing equipment. This accelerates the production process, with examples such as hearing aids being manufactured in just one day instead of one week.

1 | Implants and Prosthetics

The FDA initially approved 3D technology for dental implants, and it has since expanded to include other complex implants. A study published in the Journal of the American Academy of Orthopaedic Surgeons in 2021 concluded that 3D printing has had a significant impact on bone and cartilage restoration, potentially transforming the treatment of musculoskeletal injuries.

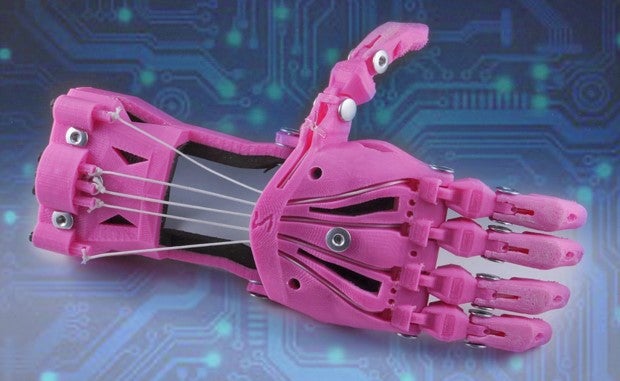

In addition, 3D technology can improve the fit and function of prosthetics. It has become accessible and affordable, enabling individuals to create their own limbs. The global volunteer community e-NABLE has already produced over 8,000 prosthetic hands and arms for people worldwide.

2 | Anatomical Models

3D printers are capable of producing highly accurate and detailed anatomical models, aiding surgeons in preparing for complex procedures, improving outcomes, and reducing costs. For example, researchers from Florida Atlantic University and the University of Virginia designed a robotic model of the human spine in 2022, helping surgeons predict the performance of interventions before surgery. The study showed 100% accuracy in determining the suitability of disc implants across five distinct postures.

A 2020 study published in Academic Radiology demonstrated that using 3D anatomic models as surgical guides reduced surgical time by an average of 62 minutes, resulting in cost savings of $3,720 per case. Another study conducted in 2021 found that surgeries were shortened by 1.5 to 2.5 hours when 3D-generated anatomical models were used as guides.

3 | Medical Equipment

Customized medical devices, including forceps, clamps, hemostats, and retractors, can be fabricated using 3D printing. One of the key benefits is the ability to rapidly make precise design modifications based on surgeon feedback.

Moreover, 3D printing has played a crucial role in addressing the increased demand for rapid deployment of medical equipment, helping to mitigate supply chain challenges. For instance, a team from Oregon Health & Science University developed a low-cost version of a ventilator using 3D printing technology, allowing for replication at less than $10 worth of materials during the recent global shortage.

The Future of 3D Printing

In 2019, bioengineers at the University of Washington School of Medicine and the UW College of Engineering achieved a breakthrough in 3D bioprinting techniques, as reported by ScienceAdvances. This success, along with advancements from the University of California Berkeley and other institutions, holds promise for producing on-demand living body tissues, blood vessels, bones, and even organs.

While 3D printing presents significant opportunities for clinical innovation, integrating this rapidly evolving technology into the highly regulated field of healthcare poses challenges. Institutions still need to address reimbursement and safety concerns. Some of the questions that need answers include:

- What will be the reimbursement models for 3D printing services and products?

- Do the benefits of establishing in-house 3D manufacturing facilities outweigh startup costs?

- How will the FDA adapt its regulatory scrutiny to meet the growing demand for 3D products?

- Which products fall outside of FDA oversight, potentially posing risks to patient safety?

As these questions are answered and technological advancements continue, 3D printing is poised to revolutionize healthcare in ways we have yet to fully imagine.

To learn more about the latest news and developments in various fields, visit Instant Global News.